TECHNOLOGY

Co-injection molding steel pipe

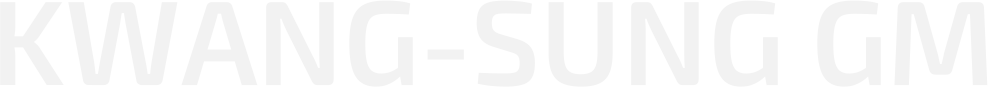

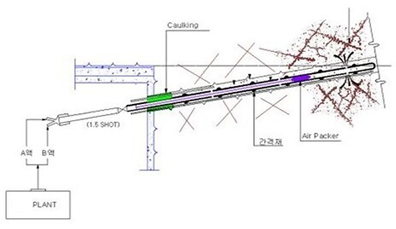

Overview of Multiple (Simultaneous) Grouting Methods

This method is an excellent method in terms of economy as it can shorten the construction period

by selectively integrating the steel pipe with the surrounding ground and forming a beam arch in the form of an umbrella,

and obtaining the secondary and reinforcement effects (bending and shear) simultaneously through the inner pipe installed

in the steel pipe without sealing work after installing the steel pipe with a specially manufactured multi-(simultaneous) grouting injection

device in an appropriate shape at the factory before tunnel excavation.

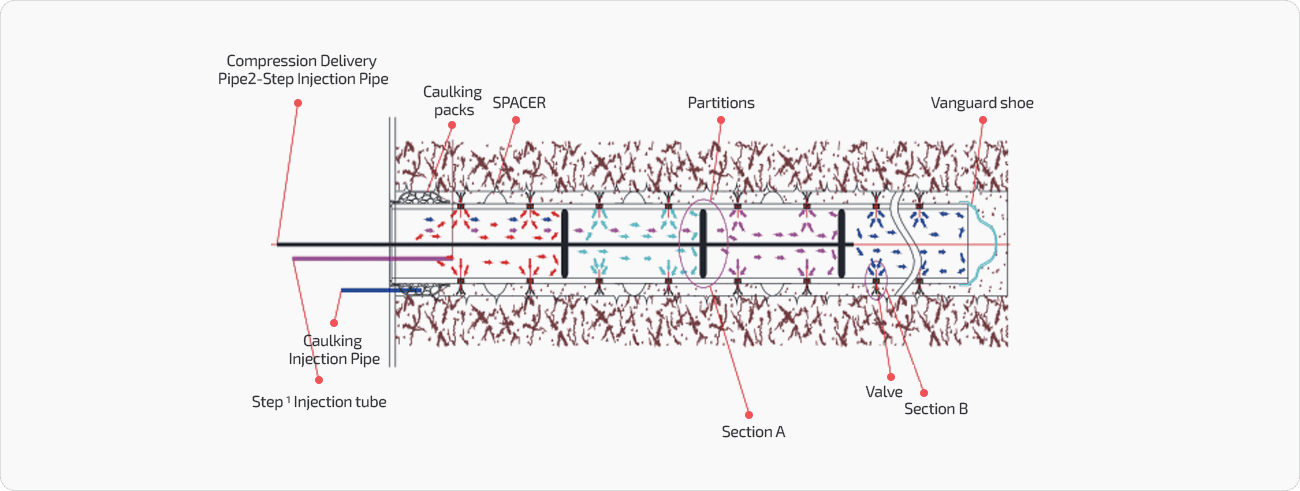

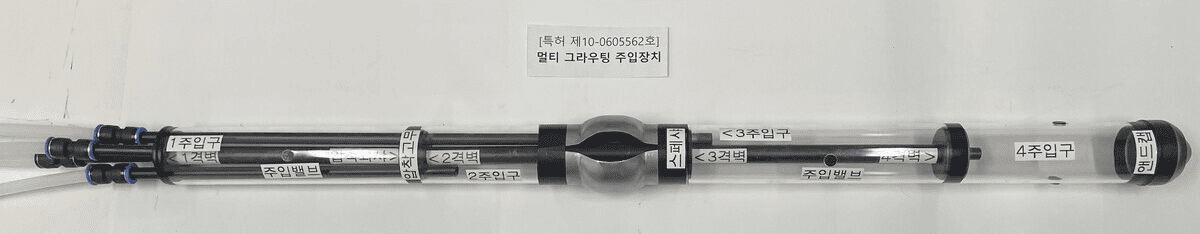

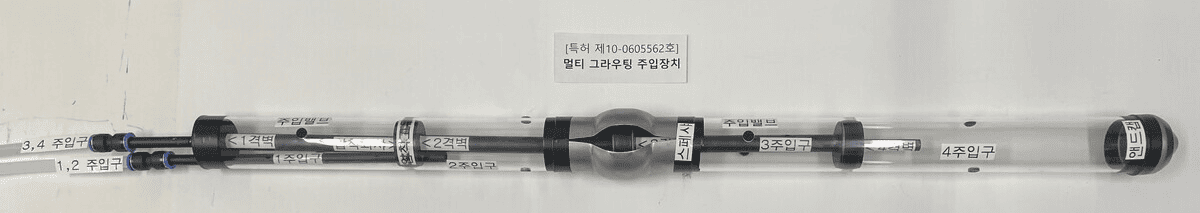

Multiple (simultaneous) steel pipe structures and System

Multiple (Simultaneous) Steel Pipe Bulkhead Installation Structure

Features of the method

| Type | Multiple (Simultaneous) Grouting Methods | Traditional multi-step grouting method |

|---|---|---|

| Method overview |  |

|

|

|

|

| Stiffeners |

|

|

| Strengths |

|

|

| Construction order | Drilling → Reinforcement insertion → Caulking → Simultaneous injection, selective injection for each SETP | Drilling → Inserting reinforcement → Caulking → Sealing → Installing air packer → Multi-stage injection for each SETP |

| Features |

|

|

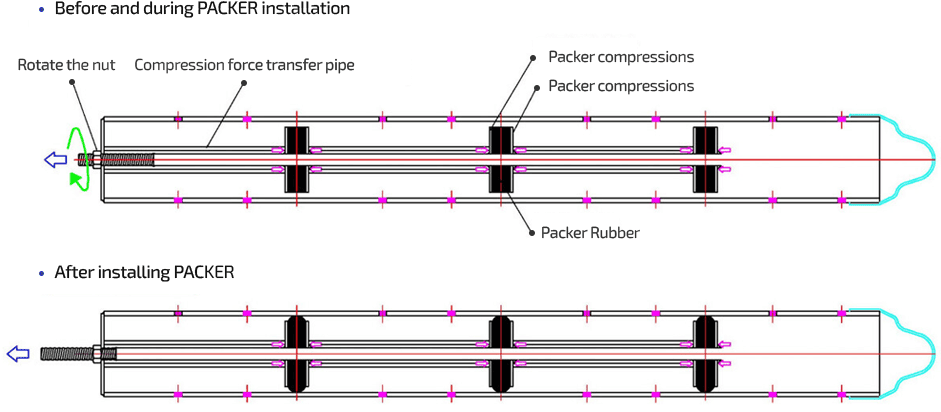

Tubular Model by System Type

4Line 4Step

2Line 4Step

ENG

ENG KOR

KOR