TECHNOLOGY

Steel Pipe · Multistage Grouting Methods

Grouting & MIRA 3D GPR SYSTEM & Soils – Geology

The technology leader Kwangsung GM Co.

The technology leader Kwangsung GM Co.

Tunnel construction for industrial infrastructure such as subways and high-speed railways is

increasing due to continuous economic growth. In particular, tunnel excavation in complex ground conditions such as soft layers of soil with high water content and highly weathered rocks in urban areas has increased, and tunnel excavation in soft ground for environmental protection purposes is

increasing in road tunnels such as highways.

increasing due to continuous economic growth. In particular, tunnel excavation in complex ground conditions such as soft layers of soil with high water content and highly weathered rocks in urban areas has increased, and tunnel excavation in soft ground for environmental protection purposes is

increasing in road tunnels such as highways.

Tunnel excavation causes stress release, so securing the stability of the shaft becomes the most important issue for tunnel excavation in soft ground. If the shaft is unstable, it is generally applied to split excavation

by leaving the core in the center of the shaft, or the side wall advanced tunneling method that reduces the starting cross-section. Even these poor excavation methods cannot solve the fundamental problem of shaft instability in tunnels such as roads and subways with relatively large cross-sections.

To solve these problems, steel pipe multi-stage construction is a highly applicable method

for securing shaft stability.

by leaving the core in the center of the shaft, or the side wall advanced tunneling method that reduces the starting cross-section. Even these poor excavation methods cannot solve the fundamental problem of shaft instability in tunnels such as roads and subways with relatively large cross-sections.

To solve these problems, steel pipe multi-stage construction is a highly applicable method

for securing shaft stability.

Formulation principles

Steel pipe multiplex is a construction method in which steel pipes are installed by forming and drilling beams

in the form of an umbrella net in the front part to be excavated in the longitudinal section,

and the ground is improved by injecting grout into the surrounding ground.

In other words, by reinforcing the ground around the tunnel with grout,

it improves the shear strength of the original ground

by integrating the steel pipe and the ground due to the cementation of the ground,

and secures the stability of the barrier through the dispersion and reduction effects,

beam effect, and local arching effect of the standing load and soil pressure applied to the tunnel.

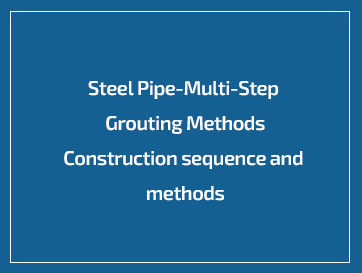

Sequence and Methods

01

Perforation

02

Inserting Steel Pipe

03

Inlet caulking

04

Sealing

05

Inject

ENG

ENG KOR

KOR