TECHNOLOGY

Continuous Nailing Method Steel Pipe

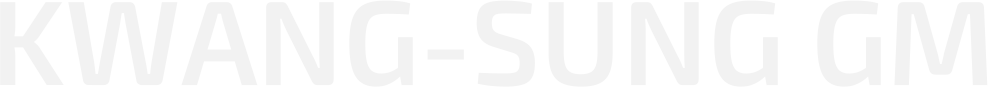

Continuous Nailing Method Overview

A method that can increase the transfer strength of the original ground and achieve the nailing effect of reinforcement

by inserting a steel pipe with a packer installed after drilling the excavated slope at regular intervals

and continuously injecting grout using a mobile packer.

Conditions

- •

Where reinforcement and permanent slope stability of cut slopes is required

- •

If the ground is already relaxed or has low self-strength

- •

Developed bedrock fracture zones or fractures

- •

Saturated slopes due to high groundwater levels

- •

Ground with little adhesion or severe weathering

- •

Ground with strong alternation of soft and hard ages due to differential weathering

Effects

- •

Increase the shear strength of the ground

- - Increasing shear strength by pressure grouting

- •

Construction cost savings

- - Reduce construction costs by simplifying sealing and caulking operations

- •

Maximize Grouting Quality Effects

- - Optional application of injection method (1.0Shot or 1.5Shot method)

- •

Air shortening effect

- - Wider installation spacing (C.T.C adjustment) enables air shortening by reducing construction quantity per unit area

- - Simplify processes to make your work more efficient

- •

Highly adaptable

- - Preventing injection material from leaving the site when using rapid payment

- - Easily respond to site conditions by changing construction patterns as ground conditions change

Features of the method

- •

Apply an injectable coking system (pay-as-you-go)

- - Cost depreciation

- - Make your work more efficient, convenient, and reliable

- - Perfect caulking effect (especially effective for groundwater runoff)

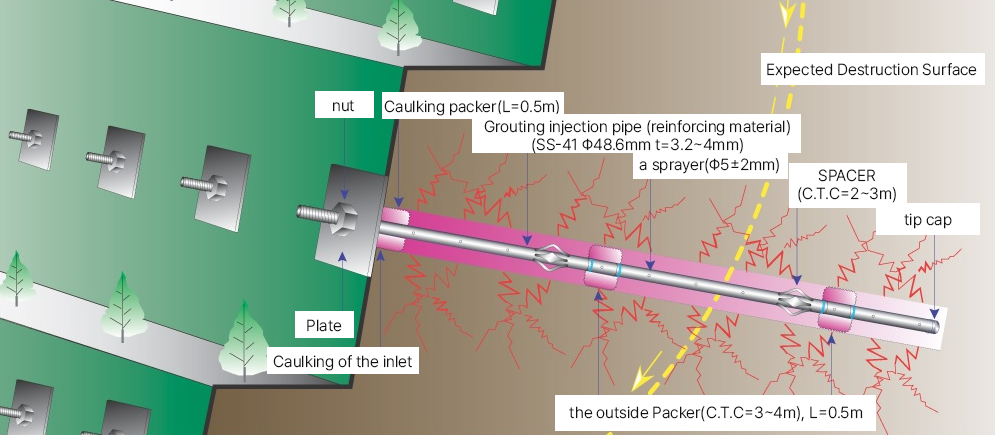

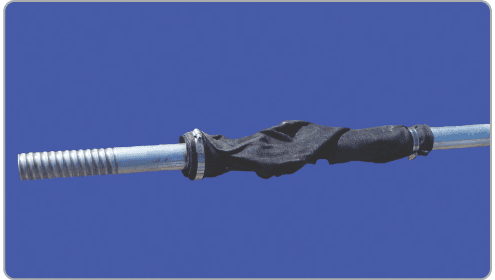

- •

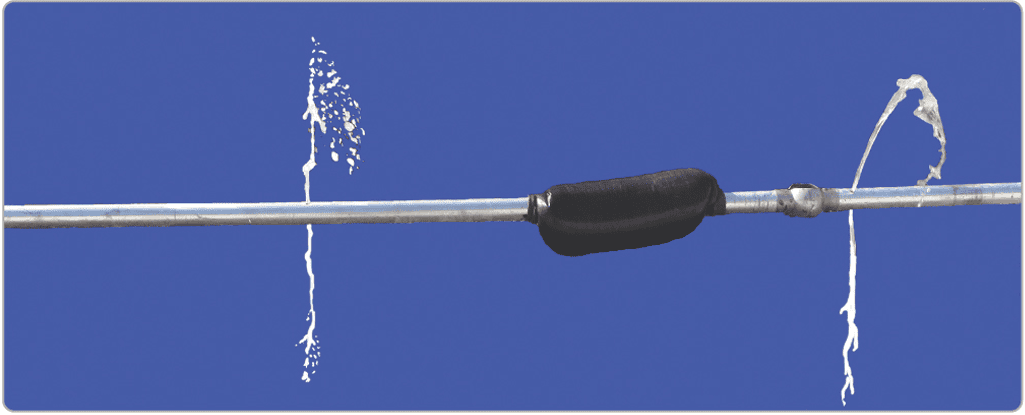

Installing an external packer

- - Anti-reflux effectiveness of infusions

- - Simplify sealing operations

- - Grouting and sealing operations at the same time

- •

Apply the Selective Grouting Method

- - Depending on ground conditions, either the 1.0-shot or 1.5-shot method can be applied

- •

Air shortening effect

- - Wider installation spacing (C.T.C adjustment) enables air shortening by reducing construction quantity per unit area

- - Simplify processes to make your work more efficient

- •

Highly adaptable

- - Preventing injection material from leaving the site when using rapid payment

- - Easily respond to site conditions by changing construction patterns as ground conditions change

ENG

ENG KOR

KOR