TECHNOLOGY

Seamless Co-Injection Reinforcement

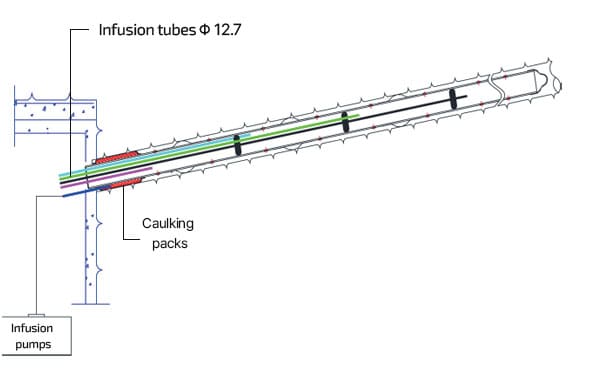

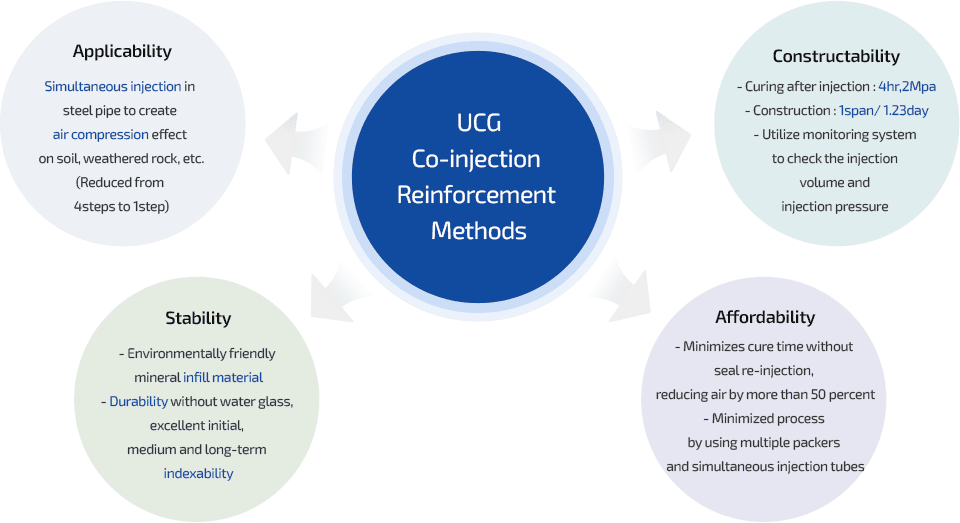

UCG (Unsealed Combi Grouting) simultaneous injection method, which installs structural steel pipes

at regular intervals in soft ground such as weathering zones before tunnel excavation,

water sections at the top of low topsoil, and fault fracture zones, and injects injected materials to obtain ground reinforcement

and secondary effects Measures in the Korea Railroad Facilities Corporation’s

“Improvement Plan for Steel Pipe Multiple Grouting Method Management” (2018. 01): The project under design shall reflect the improvements

and improvements in the construction specifications,

but if necessary, review the improved construction method such as UCG co-injection method and implement technical review.

at regular intervals in soft ground such as weathering zones before tunnel excavation,

water sections at the top of low topsoil, and fault fracture zones, and injects injected materials to obtain ground reinforcement

and secondary effects Measures in the Korea Railroad Facilities Corporation’s

“Improvement Plan for Steel Pipe Multiple Grouting Method Management” (2018. 01): The project under design shall reflect the improvements

and improvements in the construction specifications,

but if necessary, review the improved construction method such as UCG co-injection method and implement technical review.

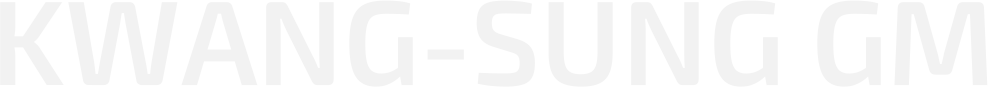

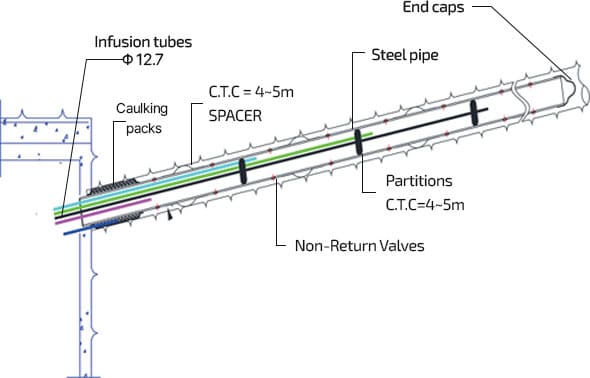

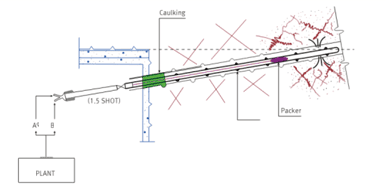

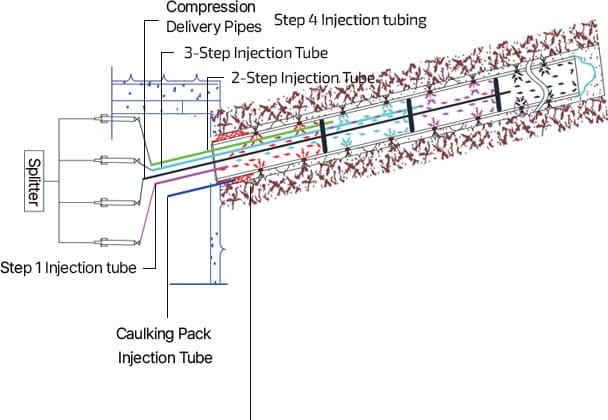

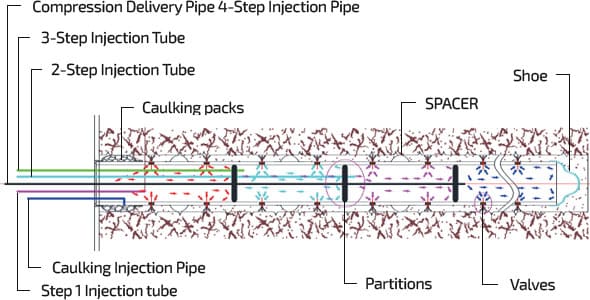

UCG Construction Sequence and Schematic Drawings

- Step 1: Perforate

- Step 2: Insert the steel pipe

- - Perforation diameter:

Φ 124m/m, perforation hole: 12.0m or more

- - Stiffener specifications:

- - Small diameter: Φ 60.5 m/m, T=4.0 m/m

- - Large Diameter: Φ114.3m/m, T=6.0m/m

- - Inlet tube sizes:

Outer diameter Φ 12.7 m/m, inner diameter Φ 9.9 m/m

- Step 3: Caulking

- - Use caulking pack between UCG co-injection steel pipe outer wall and borehole inner wall (0.3M caulk at borehole entrance)

- - Caulking:

Foamed urethane

- - Caulk must have a maximum pressure of 40 kg/cm2 or higher

Compare methods

| Type | UCG Co-Injection Method | Conventional steel pipe reinforcement methods |

|---|---|---|

| Method Features |

|

|

| Schematic |  |

|

| Strengths |

|

|

| Weaknesses |

|

|

- Step 4: Simultaneous injection

- - The injection material is a combination of cement grout and mineralized quick setting ash.

- - Injection pressure is determined by site conditions and geologic conditions.

- - Apply P = 10 to 15 kg/㎠ (ΔP=1 to 10 kg/㎠)

- Step 3: Caulking

Method Attributes

ENG

ENG KOR

KOR